Lipstick

We have two type of lipstick filling machine, one is Lipstick back filling machine, and the other is Lipstick metal mold filling machine.

Plastic mold filling

Lipstick back filling machine

Put the plastic mold on top of lipstick mechanism, and filling from back side of the mechanism.

- Merit

- Various lipstick design is possible which is difficult with metal mold.

- Demerit

- Plastic mold is less heat conduction, so cooling process is difficult, and it might have stickness.

Rubber mold filling

Lipstick back filling machine

Put the silicon mold on top of lipstick mechanism, and filling from back side of the mechanism.

- Merit

- The lipstick with logo and complicated design is possible.

- Demerit

- Rubber mold is less heat conduction, so cooling process is difficult, and it might have stickness and less shiny aspect.

And it according to the bulk formula. Rubber mold has risk of swelling.

*Our rubber mold use special material, so it doesn't have swelling, even after 1000 times filling.

Metal mold for back filling

Our recommendation

Lipstick back filling machine

Supply the mechanism in the metal mold with upside down, and filling from back side of the mechanism.

- Merit

- Metal mold has good heat conduction, so good release from metal mold, and strong for drop, because back filling, and it is easy to reduce the number of operator.

- Demerit

- The design of the lipstick is not flexibility.

Metal mold insert type

Lipstick metal mold filling machine

Filling inside of the metal mold directly, and after cooling, insert the lipstick into the mechanism.

- Merit

- Metal mold has good heat conduction, so good release from metal mold, It takes about 15 min from filling to insert.

- Demerit

- Insert the lipstick into the mechanism after filling, so weak for drop.

And many manual process, so automation is difficult.

| Machine name | Mold | Type | Design flexibility | Shiny aspect | Strength for drop | Release from mold | Strength formability | Filling formability | Automation |

|---|---|---|---|---|---|---|---|---|---|

| Lipstick back filling machine | Plastic mold | Regular | ○ | ○ | ○ | △ | △ | △ | ○ |

| Slim(Support) | ○ | △ | ○ | △ | △ | △ | |||

| Rubber mold | Regular | ○ | ○ - △ | ○ | △ | △ | △ | ○ | |

| Slim(Support) | ○ | △ | ○ | △ | △ | △ | |||

| Metal mold for back filling | Regular | △ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Slim(Support) | ○ | ○ | ○ | ○ | ○ | ○ | |||

| Lipstick metal mold filling machine | Metal mold insert type | Regular | △ | ○ | △ | ○ | ○ | ○ | △ |

| Slim(Support) | △ | ○ | △ | ○ | ○ | ○ |

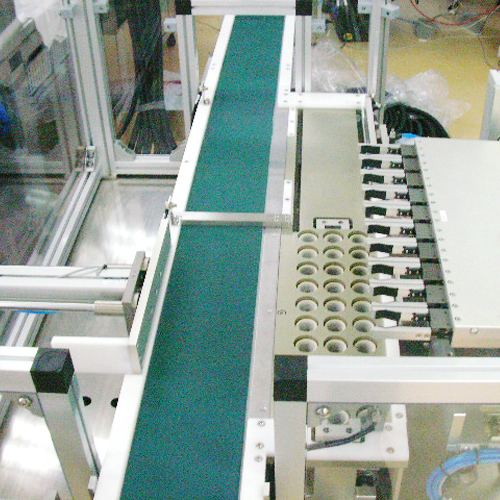

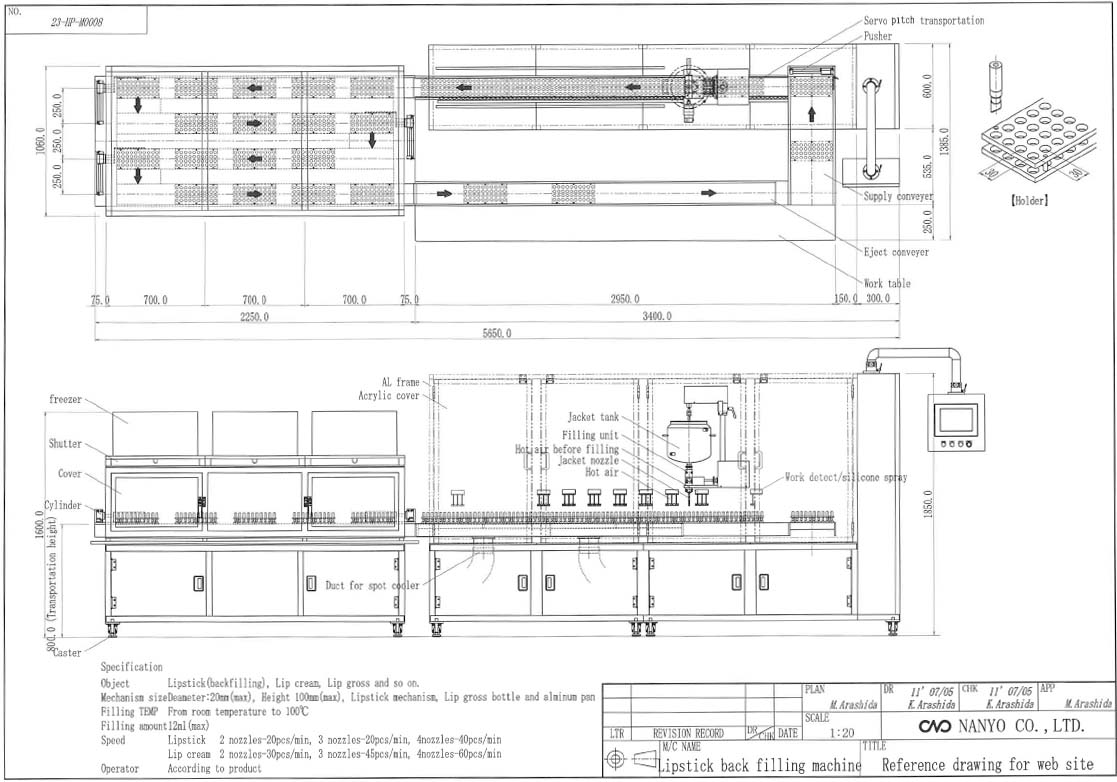

Lipstick back filling machine

This machine is for plastic mold, rubber mold and metal mold for back filling, so it is possible to use various filling method with this machine.

The filling nozzle is jacket type and hot oil circulate inside of the filling nozzle to maintain the temperature of the bulk in the filling nozzle. Then the filling nozzle goes down to inside of the mechanism to start filling with going up.

The servo motor is used for filling and up/down movement. These setting is from touch panel, so these setting has repeatability.

The feeding of the metal mold and holder is managed by servo motor.

The hot air after filling, it is possible to set the temperature, air flow, time, frequency from touch panel.

The cooling tunnel has ability to -15 degree. The setting of the cooling time is from touch panel, and control the conveyer speed inside of the cooling tunnel.

Specification

- Power source

- Electric : AC200V(3Phases) 30A-1line, 20A-2 line

Air : More than 0.5Mpa-1 line

- Object

- Lipstick(backfilling), Lip cream, Lip gross and so on.

- Mechanism size

- Deameter:20mm(max), Height 100mm(max), Lipstick mechanism, Lip gross bottle and alminum pan

- Filling TEMP

- Room temperature and from 50 to 100℃

- Filling amount

- 12ml(max)

- Speed

(Lipstick) - Filling with lifting : 2 nozzles-20pcs/min, 3 nozzles-20pcs/min, 4nozzles-40pcs/min

- Speed

(Lip cream) - Filling without filling : 2 nozzles-30pcs/min, 3 nozzles-45pcs/min, 4nozzles-60pcs/min

- Operator

- According to product

- Filling nozzle

- Jacket nozzle

- Filling

- Servo motor

- Heating before filling

- Hop air inside of the mechanism, Temperature from 40℃ to 150℃

- Hot air after filling

- Temperature from 40℃ to 150℃

- Cooling after filling

- Cooling tunnel, Temperature from -10℃ to +5℃

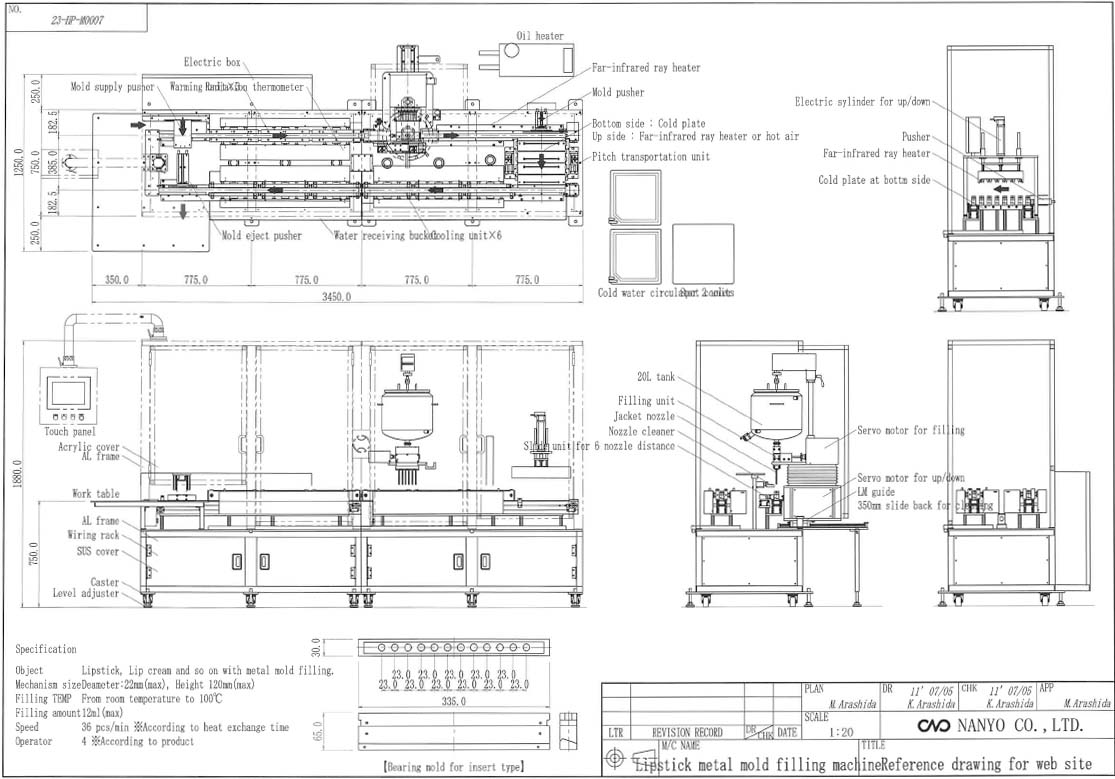

Lipstick metal mold filling machine

This lipstick filling machine with bearing metal mold is used by many cosmetic manufacture in Japan.

And there are many kind of machine which is for industrial type and small quantity production.

The metal mold have used for lipstick production from long time ago.

But recently, formula of the lipstick bulk becomes very soft, so it is difficult to produce the lipstick by the rubber mold and plastic mold with soft formula, because of the problem such as breakage, stickness and so on.

So the metal mold is remarkable mold for the soft formula now.

-Lipstick metal mold filling machine-

It takes only 15 min from filling to insert process.

All setting parameter which has influence on the product quality is from touch panel, and it is possible to save and read out these setting parameters.

The heating and cooling of the metal mold is by surface contact of the aluminum plate which is heated and cooled, so the ability of thermal exchange is very high.

The temperature of the metal mold is measured automatically just before filling, so it is possible to fill the bulk in the metal mold every time same temperature.

The filling nozzle is jacket type, so it is possible to manage the temperature of the nozzle accurately. And the filling nozzle goes down inside of the metal mold, and filling with up movement of the filling nozzle.

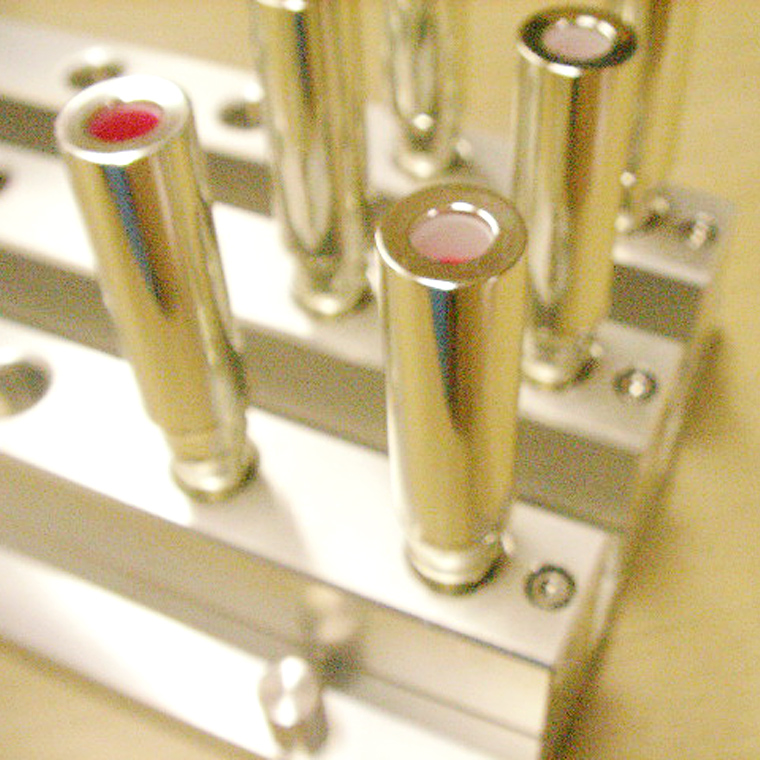

-Bearing metal mold-

The metal mold is made by special material and treatment, so it has less stickness and good shiny aspect on the lipstick surface.

It is unnecessary to separate the metal mold for picking up the lipstick, so there is no defect of the lipstick depend on the distortion inside of the metal mold.

There are 2 bearings in the both side of the metal mold, to fix the position of the upper mold and lower mold, so it is easy to take out the upper mold without breakage of the lipstick. And this bearing is used for insert machine to fix the position of the lipstick and mechanism.

-Insert machine-

It is possible to insert the lipstick in the mechanism without touching the lipstick by operator.

In the case of slim type(support type), it is easy to set the direction of the mechanism cut side.

It is possible to use for regular type and slim type lipstick.

Specification

- Power source

- Electric : AC200V(3Phases) 30A-1line, 20A-1 line

Air : More than 0.5Mpa-1 line

- Object

- Lipstick, Lip cream and so on with metal mold filling.

- Mechanism size

- Deameter:22mm(max), Height 120mm(max)

- Filling TEMP

- Room temperature and from 50 to 100℃

- Filling amount

- 12ml(max)

- Speed

- 36 pcs/min *According to heat exchange time

- Operator

- 4 *According to product

- Filling nozzle

- Jacket nozzle

- Filling

- Servo motor

- Heating before filling

- Clamp system with heated aluminum plate which has heater inside.

- Heating after filling

- Far-infrared ray heater, to cover the hole of bulk.

- Cooling after filling

- Clamp system with cooling aluminum plate which has cold a water circulate inside. Form -5℃ to 20℃