Powder press(Servo Shot)

Feature of the Servo Shot

It is powder press machine next generation type, the cosmetics color powder such as foundation and eyeshadow is pressed by servo motor.

The press parameter setting is from touch panel, and actual pressure on the powder is indicated on the screen with graphic, so it realize "visualization powder press process".

So this machine is delivered to many cosmetics manufacture company in Japan.

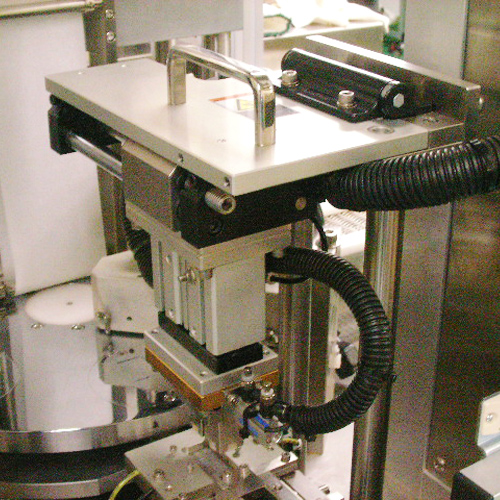

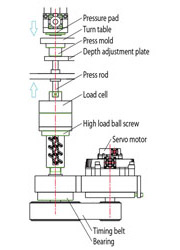

Servo motor for powder press

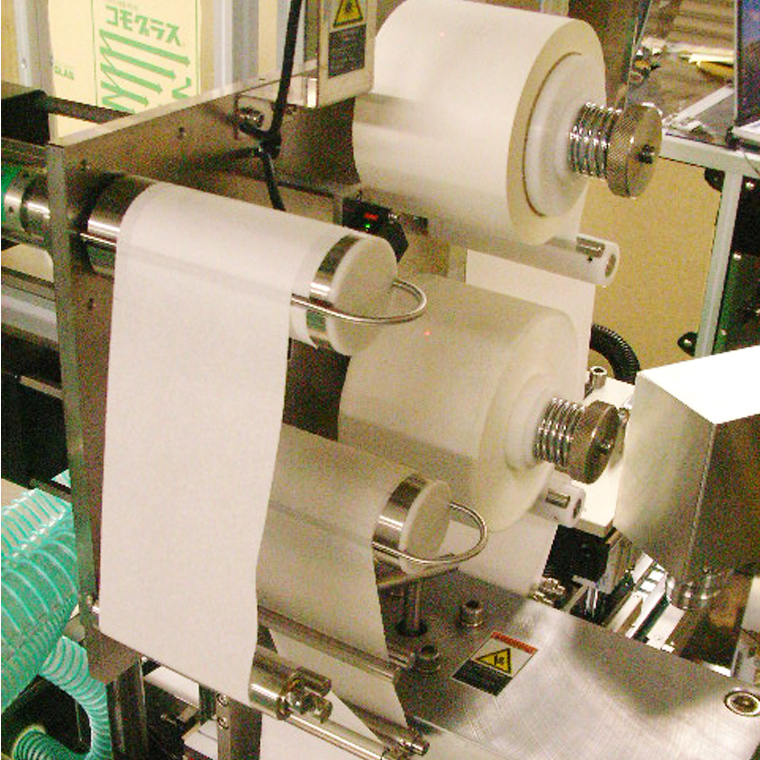

The spindle movement of servo motor is converted to linear movement for the powder press by the ball screw.

The pressure is according to "Servo motor out put", "Timing pulley ratio", and "Lead of the ball screw".

So it is possible to set the press parameter accurately from touch panel by this press mechanism with servo motor.

Comparing with hydraulic powder press machine as conventional model, this machine is superior in the point of response, repeatability, operability, less noise and hygienically(No oil mist flow in the air).

Powder press parameter

The press parameter setting is by "Time(sec)", "Speed(mm/sec)", "Pressure(KN)", "UP or DOWN", and "Block(Depend on how many different pressure is necessary)".

All of these press parameter setting is from touch panel, and it is possible to memorize these parameter.

The actual pressure to the powder in the moment of powder press is indicated on the screen every time after each press.

And it is possible to write the each actual pressure data in the SD card, so it is possible to analyse these data on the PC with the application software EXCEL.

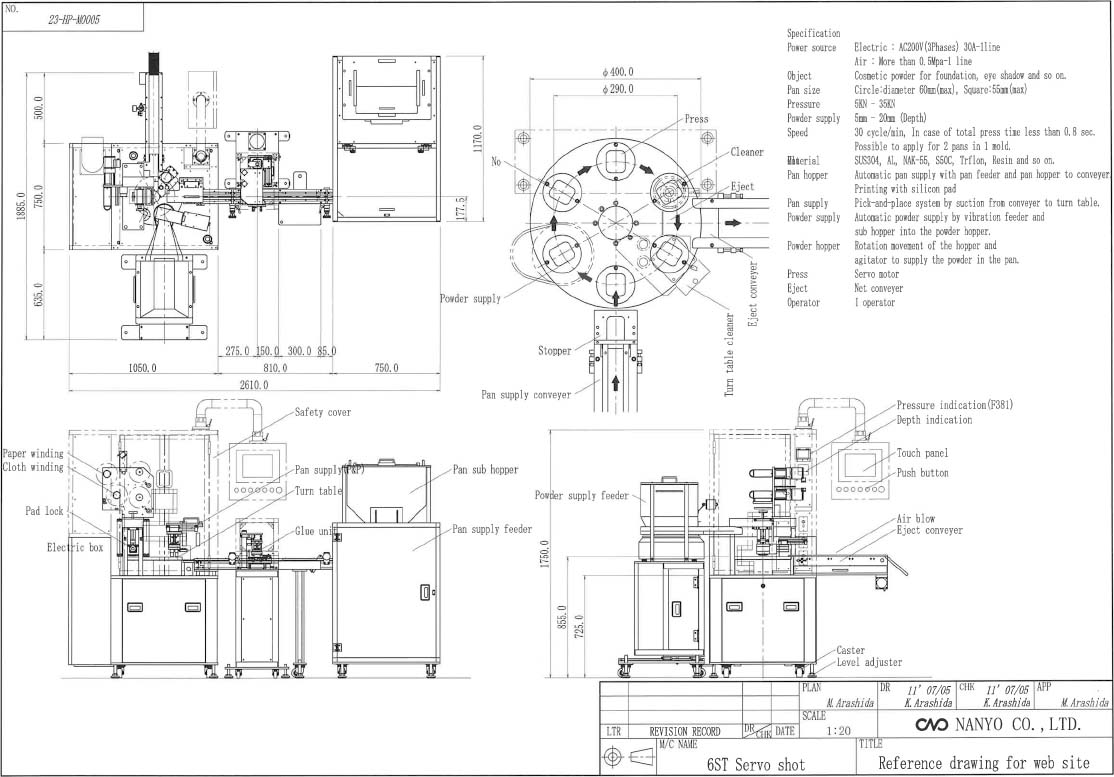

6ST Servo shot

6st servo shot is industrial powder press machine for foundation and eye shadow, and uses the servo motor for powder press.

The press parameter setting is from touch panel, and it is possible to adjust many kind of press parameter according to each powder formula.

The servo shot is new technology, which is replacement of the hydraulic powder press machine.

Comparing with hydraulic powder press machine as conventional model, this machine is superior in the point of high response, repeatability, operability and environment(Less noise and energy consumption).

All setting parameter which has influence on the product quality is from touch panel, and it is possible to save and read out these setting parameters.

The servo motor for powder press is operated by torque controll, and it is possible to adjust many kind of press parameter.

The actual pressure to the powder in the moment of powder press is indicated on the screen every time after each press. And it is possible to write the each actual pressure data in the SD card, so it is possible to analyse these actual pressure data on the PC EXCEL.

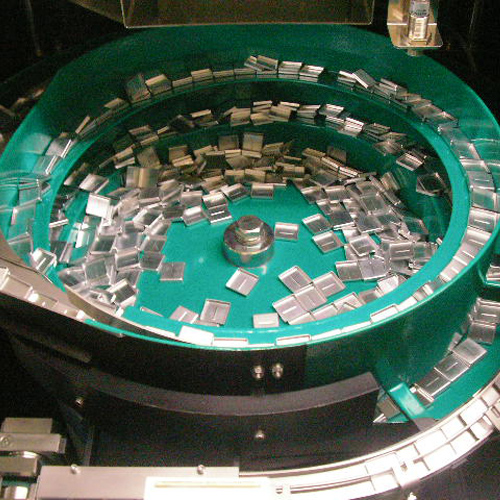

The pan supply from conveyer to turn table is pick-and-place system, to reduce the jam of the pan in this position.

In case of 2 cavities in 1 mold, pick-and-place system is also used, to reduce the powder weight and hardness different.

To increase the strength for drop, it is possible to put glue in the pan with silicon pad printing system before powder supply, so the glue doesn't disperse, and possible to put the glue in the pan equality.

The pan supply feeder has the sub hopper, it is possible to supply about 3000 pcs of the foundation pan in the sub hopper. The pan supply feeder has the noise reduction cover, and noise level from pan supply feeder is less than 68 dB.

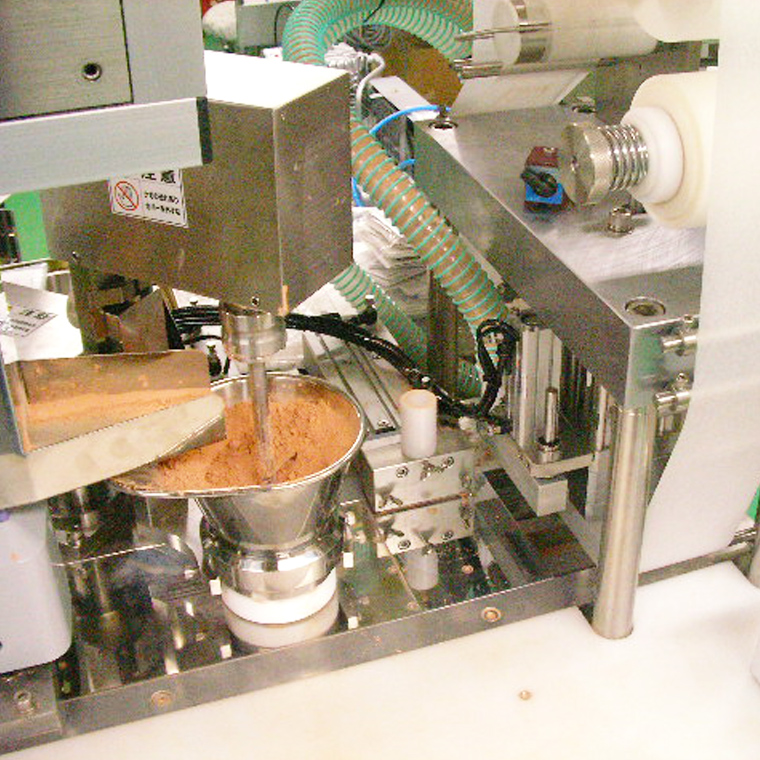

The height of the powder in the hopper is detected by sensor, so the powder is supplied in the hopper automatically from feeder, according to the powder height in the hopper which is detected by sensor.

BIM(back filling) process flow

- Automatic pan supply with pan feeder

- Put glue in the pan

- Pan supply in turn table

- Powder supply in the pan

- Powder press

- Product surface dust collector

- Eject

- Take out product by operator manually

Specification

- Power source

- Electric : AC200V(3Phases) 30A-1line

Air : More than 0.5Mpa-1 line

- Object

- Cosmetic powder for foundation, eye shadow and so on.

- Pan size

- Circle:diameter 60mm(max), Square:55mm(max)

- Pressure

- 5KN - 35KN

- Powder supply

- 5mm - 20mm (Depth)

- Speed

- 30 cycle/min, In case of total press time less than 0.8 sec.

Possible to apply for 2 pans in 1 mold.

- Material

- SUS304, AL, NAK-55, S50C, Trflon, Resin and so on.

- Pan hopper

- Automatic pan supply with pan feeder and pan hopper to conveyer.

- Glue

- Printing with silicon pad

In Japan, some product have glue in the pan, to increase the strength for drop.

- Pan supply

- Pick-and-place system by suction from conveyer to turn table.

- Powder supply

- Automatic powder supply by vibration feeder and sub hopper into the powder hopper.

- Powder hopper

- Rotation movement of the hopper and agitator to supply the powder in the pan.

- Press

- Servo motor

- Eject

- Net conveyer

- Operator

- 1 operator

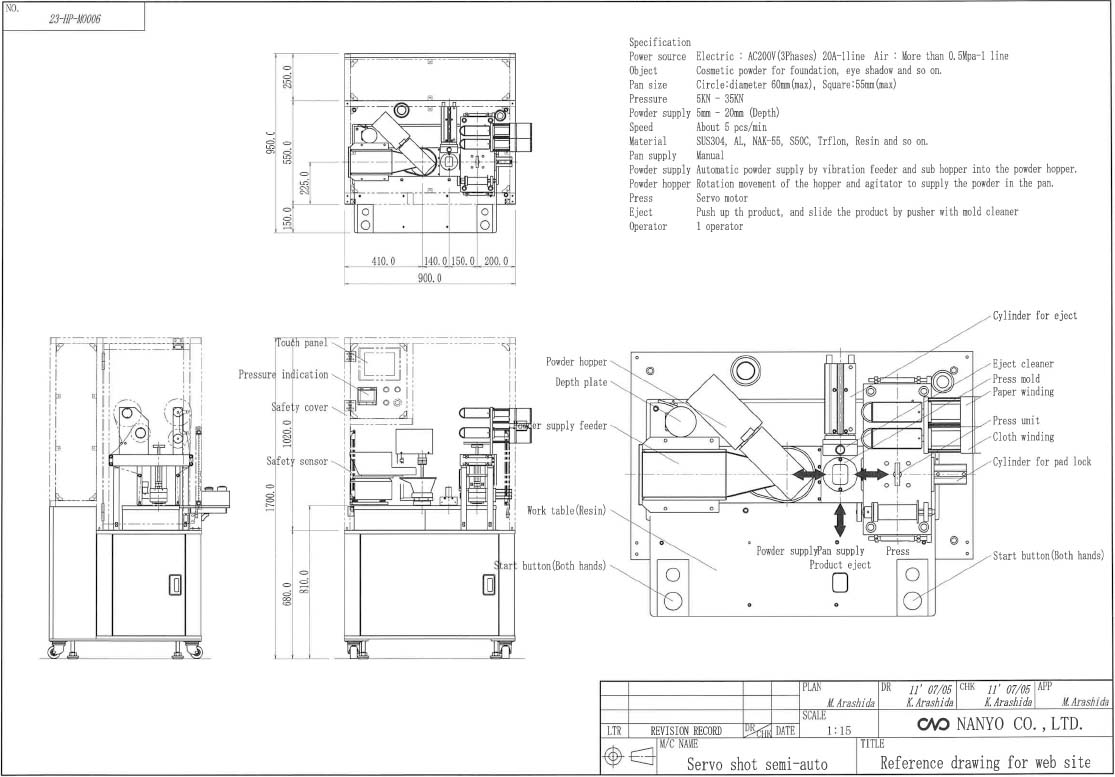

Servo shot semi-auto

Servo shot semi-auto is for small quantity production, and it can be pilot powder press machine.

This machine has same powder supply system and press system with 6ST servo shot, so it is possible to have test and small quantity production by same parameter with 6st servo shot.

All setting parameter which has influence on the product quality is from touch panel, and it is possible to save and read out these setting parameters.

The servo motor for press is operated by torque controll, and it is possible to adjust many kind of press parameter.

The actual pressure to the powder in the moment of powder press is indicated on the screen every time after each press. And it is possible to write the each actual pressure data in the SD card, so it is possible to analyse these actual pressure data on the PC EXCEL.

Process

- Prepare pan and powder

- Put the pan in the mold,push 2 start buttons

- Mold moves to left, and powder supply in the pan

- Mold moves to right, and powder press

- Mold moves to middle

- Product is pushed up, and eject the product by pusher with mold cleaning

Specification

- Power source

- Electric : AC200V(3Phases) 20A-1line

Air : More than 0.5Mpa-1 line

- Object

- Cosmetic powder for foundation, eye shadow and so on.

- Pan size

- Circle:diameter 60mm(max), Square:55mm(max)

- Pressure

- 5KN - 35KN

- Powder supply

- 5mm - 20mm (Depth)

- Speed

- About 5 pcs/min

- Material

- SUS304, AL, NAK-55, S50C, Trflon, Resin and so on.

- Pan supply

- Manual

- Powder supply

- Automatic powder supply by vibration feeder and sub hopper into the powder hopper.

- Powder hopper

- Rotation movement of the hopper and agitator to supply the powder in the pan.

- Press

- Servo motor

- Eject

- Push up the product, and slide the product by pusher with mold cleaner

- Operator

- 1 operator